Imperial Green guarantees the most reliable gas interlock design and installation methods available.

Gas Interlock

Systems.

What is a Gas Interlock System?

A gas interlock system is a safety device used in commercial kitchens to prevent the gas supply from being turned on unless the ventilation system is operating correctly. This helps to avoid dangerous build-ups of gas and ensures compliance with safety regulations.

Gas interlock systems are crucial for maintaining safety in commercial kitchens. These systems ensure that the gas supply is only activated when the ventilation system is functioning properly, preventing dangerous gas build-ups. Compliance with these safety measures is enforced by various governing bodies in the UK, such as the Health and Safety Executive (HSE) and in accordance with British Standard BS 6173. Additionally, regulations like the Gas Safety (Installation and Use) Regulations 1998 and the IGEM/UP/19 standards mandate strict safety protocols to protect kitchen staff and patrons, ensuring a safe working environment.

Gas Interlock Panel

Controls and monitors gas supply safety in commercial kitchens.

Fan Operation Proving Device

Ensures ventilation fans are functioning properly.

Manual Emergency Devices

Allows manual shutdown of gas supply in emergencies.

Gas Solenoid Valve

Controls gas flow, shutting off in unsafe conditions.

DIFFERENT TYPES OF SYSTEM

General guide on what systems we design and install and their applications.

GAS INTERLOCK SYSTEM

A standard gas interlock system is typically used for new and basic kitchen ventilation systems with gas appliances, even when these appliances are fitted with flame failure devices. While flame failure devices ensure that no gas leaks from an appliance if the flame is extinguished, the gas interlock system adds another layer of safety by ensuring that gas flow is automatically cut off if the ventilation system is not functioning properly. This prevents gas accumulation and potential hazards, providing comprehensive protection for commercial kitchens.

GAS PROVING SYSTEM

Gas proving systems are a type of gas interlock system that includes a gas pressure sensor or switch. These systems are generally used for appliances that do not have a built-in flame failure device or for customers who desire an additional layer of safety.

The system operates by purging the gas line to reach a specified pressure set point, confirming that there are no gas leaks in the system. Once the purge is complete and the absence of leaks is verified, the gas valve opens to allow gas flow to the appliances, in conjunction with the operation of the extract and supply fans. This ensures that the gas supply is safe and reliable, providing enhanced protection for the commercial kitchen environment.

(The image above is of a gas pressure sensor that attaches to a gas solenoid valve)

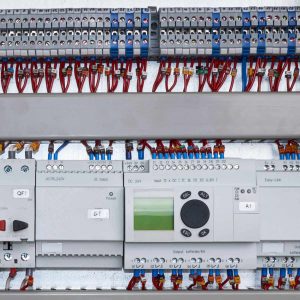

CUSTOM GAS INTERLOCK CONTROL SYSTEM

Imperial Green Systems designs and builds custom control panels specifically for gas interlocking purposes. The need for a custom control panel typically arises when multiple control strategies are required beyond the capabilities of a standard gas interlock panel.

For instance, in the event of a fire alarm, a custom control panel can be programmed to shut down the supply fan while keeping the extract fan operational, ensuring safe evacuation and effective smoke control. Additionally, the control panel can monitor filtration methods to ensure they are functioning correctly. Cooking can only proceed if the filtration systems are working properly, maintaining a safe and compliant kitchen environment.

How we guarantee the reliability of your gas interlock system

None of our gas interlock systems are pre-packaged from wholesalers or manufacturers. Each system is carefully specified to meet your unique requirements, with a focus on reliability and maintainability.

We use panels with standard features

We use gas interlock panels without unnecessary features like built-in fan control and current sensing whenever possible. In our experience, the more features a system has, the more likely something can go wrong.

We don't want to be called out for repairs, and you don't want to incur the cost of a callout!

Separate fan controls

Whether it’s an inverter, DOL starter, transformer, or electronic speed controller, we use a method that monitors the current effectively.

Separating the fan wiring from the gas interlock panel wiring allows for effective fault finding. In many cases, especially with the use of three-phase fans, splitting the wiring and using joints can have a detrimental effect on both your fan wiring and your gas interlock system.

Manual activation devices

We use yellow manual call points wherever possible over the use of stop buttons. This helps mitigate the nuisance activation of the gas interlock system from bumping into stop buttons.

Our call points are made by KAC which is the most popular brand in the UK, where you will likely find the test keys are compatible with your fire alarm system.